Monitoring of the conveyor belt

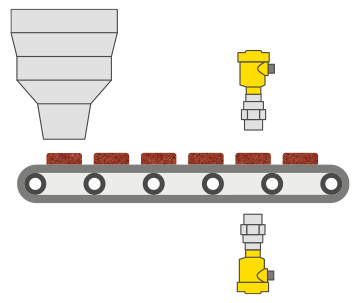

Meat pellets conveyor

Monitoring of the conveyor belt

Process data

Measuring task

Monitoring of conveyor belt

Measuring point

Conveyor belt

Measuring range up to

1 m

Medium

Meatballs

Process temperature

+5 … +25 °C

Process pressure

0 … 0 bar

Special challenges

Strongly adhesive medium

Application

The finished meat pellets and kibbles are fed onto a conveyor belt ready for packaging to be sold as pet foods. In order to ensure a continuous supply of meatballs, the conveyor belt requires careful monitoring.

Your benefit

Reliable

Fast reaction time guarantees a timely shutdown

Cost effective

Optimum performance through non-contact measurement

User friendly

Simple setup and commissioning

Recommended products

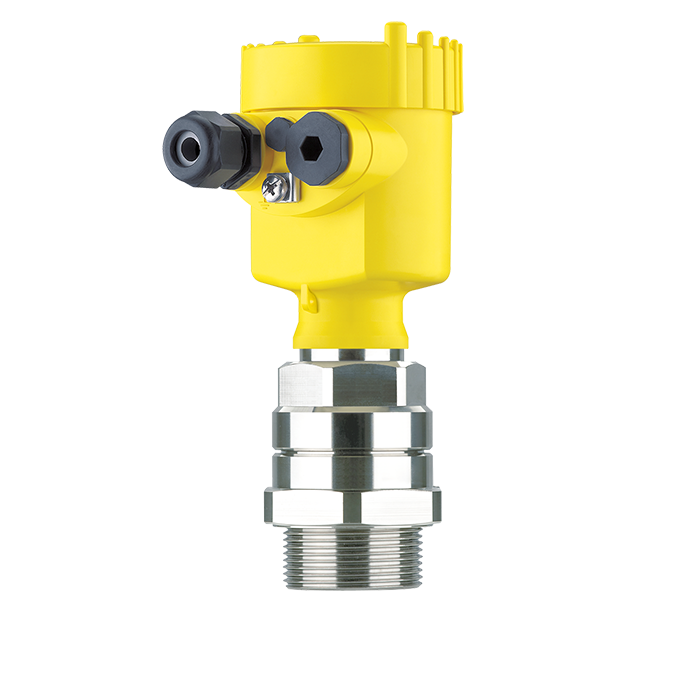

VEGAMIP 61

Microwave sensor for non-contact monitoring on a conveyor belt

- Fast switching ensures safe shutdown

- Simple setup and commissioning with control keys

- Simple installation, measurement right through conveyor belt and viewing window

Measuring range - Distance

100 m

Process temperature

-40 ... 80 °C

Process pressure

-1 ... 4 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Monitoring of the conveyor belt

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -