Level and pressure measurement during the mixing of ice cream ingredients

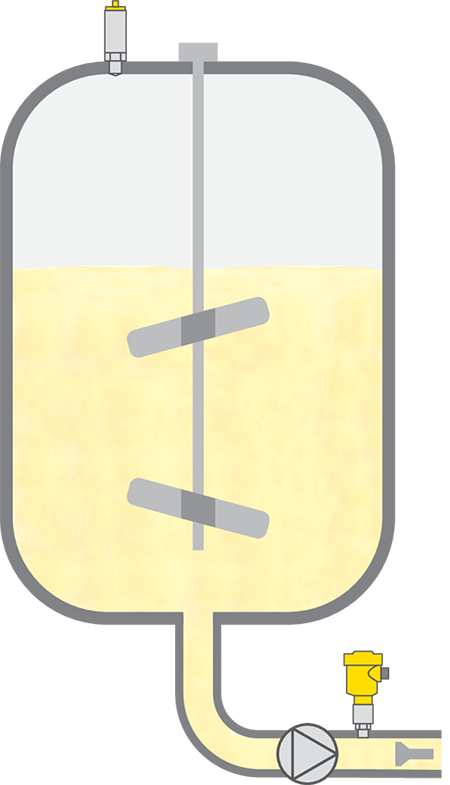

Ice cream "Premix" mixer

Level and pressure measurement during the mixing of ice cream ingredients

Process data

Measuring task

Level and pressure measurement

Measuring point

Tank/pipe

Measuring range up to

1.5 m

Medium

Ice cream

Process temperature

0 … +125 °C

Process pressure

-1 … +5 bar

Special challenges

Large temperature fluctuations, condensate

Application

The ingredients for making ice cream are accurately weighed and fed into a mixing tank, where the "premix" is made. Afterwards, the premix is passed through the homogenizer at a pressure of about 140 bar and then pasteurized at 80 °C. The level in the premix vessel and the pressure in the pipeline leading to the homogenizer need to be continuously monitored to ensure continuous ice cream production.

Your benefit

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

Short delivery time and standardized operation thanks to plics® concept

User friendly

Simple installation due to small dimensions

Recommended products

VEGAPULS 64

Continuous level measurement with radar in the "premix"

- Non-contact measurement, unaffected by agitators even in small vessels thanks to extremely tight focusing

- Flange with encapsulated antenna system allows optimal CIP and SIP cleaning

- Reliable measurement, resistant to condensation

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

VEGABAR 83

Pressure transmitter for monitoring pressure in a homogenizer

- Robust diaphragm easily handles high pressures

- Resistant to vacuum during the cleaning cycle

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 1000 bar

Process temperature

-40 ... 200 °C

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level and pressure measurement during the mixing of ice cream ingredients

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -