Level measurement and point level detection in tanks for liquid fuels

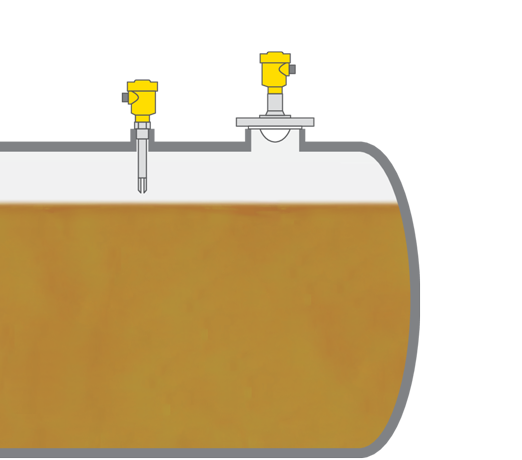

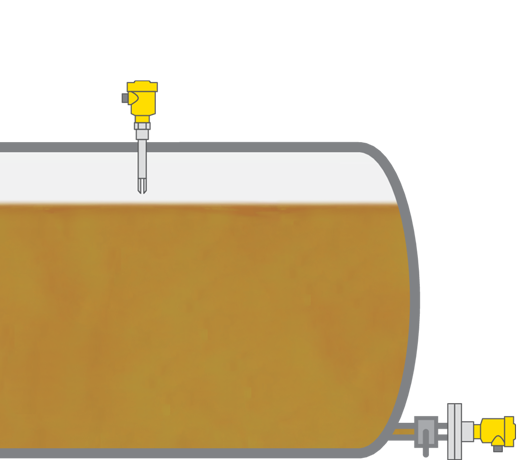

Tank for liquid fuels

Level measurement and point level detection in tanks for liquid fuels

|

|

Process data

Measuring task

Level measurement and point level detection

Measuring point

Tank

Measuring range up to

5 m

Medium

Fuel oil, heavy oil

Process temperature

-10 … +80 °C

Process pressure

0 … 0 bar

Special challenges

Media with low dielectric constant

Application

Large amounts of energy are needed to burn clinker in rotary kilns. Substitute liquid fuels such as spent oils or recovered solvents are often used for this purpose. The fuel storage tanks often contain a mixture of solvents, which can produce fumes and vapours in the air space. Due to the large amount of energy needed in cement production, the fuel inputs represent a significant cost factor, so accurate level measurement is essential.

Your benefit

Reliable

Reliable measurement under all operating conditions

Cost effective

Optimal storage

User friendly

Maintenance-free operation

Recommended products

VEGAPULS 64

Level measurement with radar in tanks for liquid fuels

- Good focusing means reliable measurement right down to the bottom, thanks to 80 GHz technology

- Reliable measurement, independent of product properties

- Simple installation in small mounting sockets allows universal use

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

VEGASWING 63

Vibrating level switch for protection against overfilling in liquid fuel tanks

- Accurate and reliable function through product-independent switching Point

- Reliable point level detection in compliance with SIL2 and WHG

- Adjustment-free setup and maintenance-free operation

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement and point level detection in tanks for liquid fuels

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -