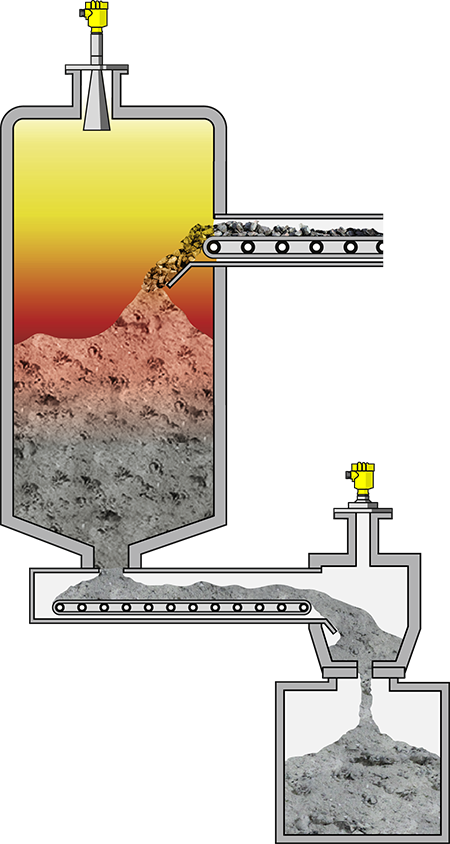

Level measurement in the pyrolysis chamber and in the ash discharger

Pyrolysis chamber and ash container

Level measurement in the pyrolysis chamber and in the ash discharger

Process data

Measuring task

Level measurement

Measuring point

Container

Measuring range up to

2.5 m

Medium

Hot ash

Process temperature

+40 … +200 °C

Process pressure

0 … +2 bar

Special challenges

Measurement through narrow chute, poorly reflecting medium, measurement during filling

Application

Waste incineration converts domestic and commercial waste into combustible gases and ash. Pyrolysis is carried out in the absence of air at temperatures up to 500 °C. The intermediate product, charcoal, is then further burned by adding air. Ash and synthesis gas with high thermal content are the end products. For continuous operation, the vessel must be loaded and emptied automatically. To this end, the level of material in the pyrolysis chamber and in the ash pan has to be measured.

Your benefit

Reliable

Reliable backup detection in the chute

Cost effective

Optimal utilization of the ash container volume

User friendly

Low maintenance requirements thanks to non-contact measurement

Recommended products

VEGAPULS 68

Non-contact level measurement with radar in the ash container

- Precise measurement through narrow chute thanks to small beam angle

- Reliable measurement, even with poorly reflecting medium

- Integrated rinsing connection as the basis for automated cleaning

Measuring range - Distance

75 m

Process temperature

-196 ... 450 °C

Process pressure

-1 ... 160 bar

VEGAPULS 69

Level measurement with radar in the pyrolysis chamber

- Reliable measurement despite high temperatures

- Unaffected by dust, smoke and other harsh environmental conditions

- Maintenance-free thanks to non-contact measurement

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

Recommended products

VEGAPULS 69

The ideal solution for this application is the radar sensor VEGAPULS 69. With its small beam angle, the instrument measures with extreme precision through the narrow chute down to the ash container. Thanks to the high dynamic range of its measuring method, it gathers level data reliably in spite of the poor reflectivity of the ash. The non-contact measuring method also makes the instrument virtually maintenance free. VEGAPULS 69 prevents backup and ensures that the ash container is always emptied at the right time, guaranteeing reliable, continuous operation of the plant.

User benefits

User benefits

- Reliable backup detection in the chute for reliable, continuous operation of the plant

- Emptying on demand ensures optimal utilization of the ash container

- Simple conversion of existing measuring points

- Low maintenance requirements thanks to non-contact measurement

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement in the pyrolysis chamber and in the ash discharger

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -