Level measurement and point level detection in coke silos

Coke silo

Level measurement and point level detection in coke silos

Process data

Measuring task

Level measurement and point level detection

Measuring point

Silo

Measuring range up to

25 m

Medium

Coke

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Heavy dust, abrasive medium

Application

Coke is often stored in very tall silos. Coke product is also susceptible to plugging the chute as the vessel empties. To accurately measure and monitor the level in these silos, especially during fill/empty stages, the instrumentation must be able to perform reliably, even under these conditions.

Your benefit

Reliable

Long measurement sensor lifespan because no contact with medium

Cost effective

Wear and maintenance-free

User friendly

Easy installation and setup

Recommended products

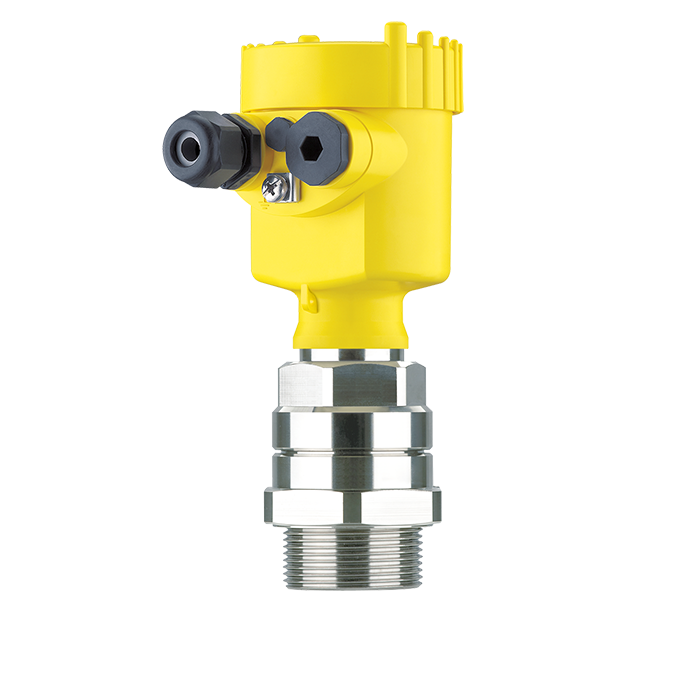

VEGAPULS 69

Radar sensor for continuous level measurement in coke silos

- Reliable measurement unaffected by buildup

- Radar principle is unaffected by temperature, gas and dust

- Non-contact measurement is wear and maintenance-free

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

VEGAMIP 61

Microwave barrier system for plugged chute detection of coke silo

- Non-contact measurement ensures maintenance-free service in abrasive media

- Reliable measurement, immune to dust and buildup

- Simple adjustment saves time and costs for setup

Measuring range - Distance

100 m

Process temperature

-40 ... 80 °C

Process pressure

-1 ... 4 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement and point level detection in coke silos

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -