Density, level measurement and point level detection in coke drums

Coke drums

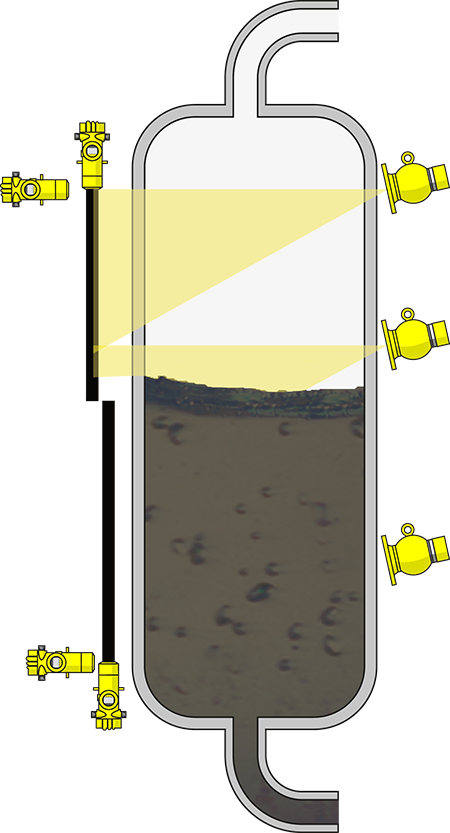

Density, level measurement and point level detection in coke drums

Process data

Measuring task

Density and level measurement, point level detection

Measuring point

Tank

Measuring range up to

18 m

Medium

Heavy residual oil

Process temperature

+400 … +480 °C

Process pressure

+3 …+8 bar

Special challenges

High temperature, heavy foam, buildup

Application

Delayed coking units are a critical step in the refining process - this is where downtime, inefficiency, and overfill are not an option. They generate extreme heat during operation and are very large vessels. By monitoring upper vapour phase density, operators can reduce antifoam carry-over and improve continuous productivity with accurate level measurement.

Your benefit

Reliable

Safe measurement even under extreme conditions

Cost effective

Reduced need of foam agents thanks to continuous foam monitoring

User friendly

Easy installation

Recommended products

FIBERTRAC 31

Radiation-based sensor for continuous level measurement in coke drums

- Lightweight construction eliminates need for cranes or special rigging for mounting

- Long detector length minimizes the need for additional platform construction

- RS485 gauge to gauge communication network offers extensive diagnostics and reduced troubleshooting time

Measuring range - Distance

7 m

Process temperature

-

Process pressure

-

MINITRAC 31

Radiation-based density and point level measurement in coke drums

- Non-contact measurement unaffected by fluid viscosity, deflection or refractive properties

- Monitors anti-foam injection effectiveness

- RS485 gauge to gauge communication network offers extensive diagnostics and reduced troubleshooting time

- Re-zeroing of the system with each cycle improves accuracy

Measuring range - Distance

-

Process temperature

-40 ... 60 °C

Process pressure

-

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Density, level measurement and point level detection in coke drums

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -