Level and flow measurement in the hydraulic oil station

Hydraulic oil station

Level and flow measurement in the hydraulic oil station

|

|

Process data

Measuring task

Level and flow measurement

Measuring point

Tank

Measuring range up to

2 m

Medium

Machine oil

Process temperature

+20 … +80 °C

Process pressure

+5 … +6 bar

Special challenges

High pressures

Application

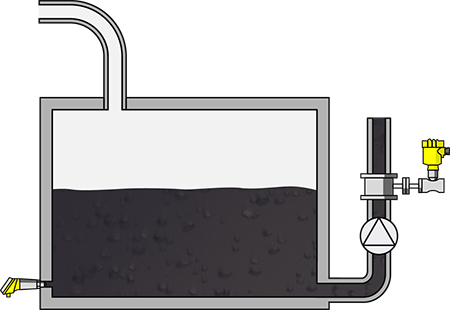

In the press section of a paper machine, very high pressures are needed for dewatering the stock. Hydraulic oil stations provide the supply to the various parts of the machine as well as filtering and cooling the recirculating lubrication system. Integrated pumps provide oil to the required locations and to enable fully automatic operation of the station, the flow rate and the level in the supply tanks must be measured.

Your benefit

Reliable

Reliable measurements ensure consistent operation of the paper machine

Cost effective

Differential pressure transmitters with pitot tube for low-cost oil flow measurement

User friendly

Convenient reading of the level directly at the measuring point

Recommended products

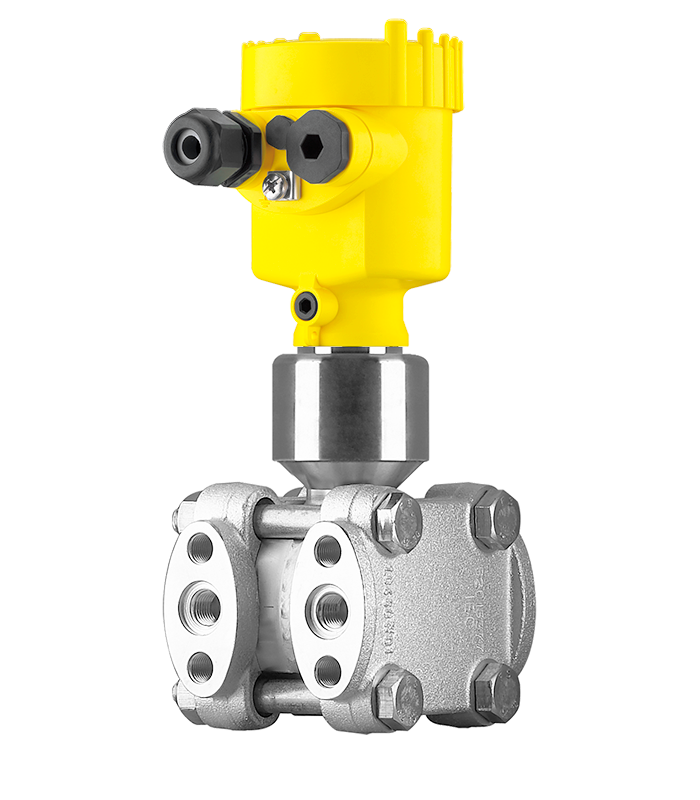

VEGADIF 85

Flow measurement in the hydraulic oil line via differential pressure

- Reliable flow values ensure high operational reliability of the paper machine

- Cost-effective flow measurement with differential pressure and pitot tube

- Direct mounting of the differential pressure transmitter at the measuring point

Measuring range - Pressure

-40 ... 40 bar

Process temperature

-40 ... 120 °C

Process pressure

-1 ... 420 bar

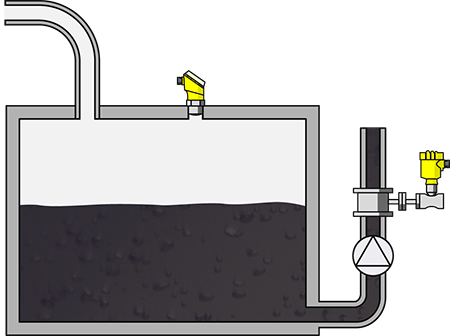

VEGAPULS 64

Level measurement with radar in the oil supply tank

- Exact measurement, independent of medium properties

- Measurement down to the bottom even in case of media with low dielectric constant

- Optimum use of the vessel volume through small blocking distances

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level and flow measurement in the hydraulic oil station

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -