Pressure measurement in the pressure screen

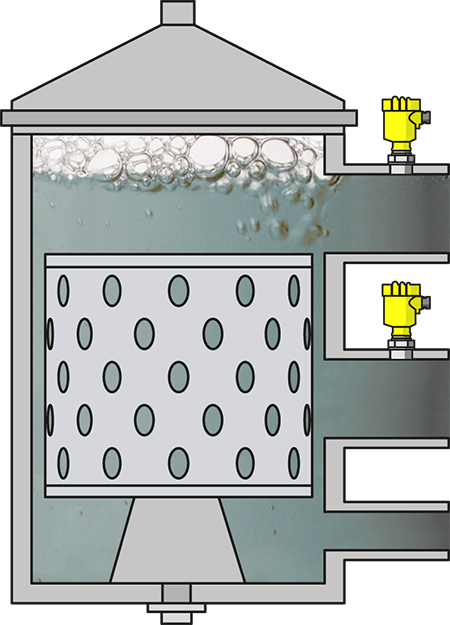

Pressure screen

Pressure measurement in the pressure screen

Process data

Measuring task

Pressure measurement

Measuring point

Pressure screen

Measuring range up to

2 bar

Medium

Paper suspension

Process temperature

+20 … +50 °C

Process pressure

+1.5 … +2 bar

Special challenges

Pressure surges, abrasion, contaminants in the suspension

Application

Pressure screens are used to filter out impurities and separate fibres in stock preparation. A rotating screen basket inside the filter does the actual filtering. Pressure screens have an inlet for the suspension, an outlet for accepted stock and a discharge for rejected stock and contaminants. The process conditions are characterized by pressure surges as well as abrasion and contaminants in the stock. Efficient screening requires a controlled pressure difference between inlet and outlet, which therefore requires continuous, reliable measurement.

Your benefit

Reliable

Reliable measurement despite strong vibration

Cost effective

High abrasion resistance guarantees long operation

User friendly

Self-cleaning and maintenance-free thanks to front-flush mounting

Recommended products

VEGABAR 82

Pressure transmitter for pressure measurement in the pressure screen

- Front-flush installation with self-cleaning effect

- High abrasion resistant ceramic for a long service life

- Highly resistant to overload from pressure surges

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 100 bar

Process temperature

-40 ... 150 °C

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Pressure measurement in the pressure screen

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -