Level measurement in a pump tank

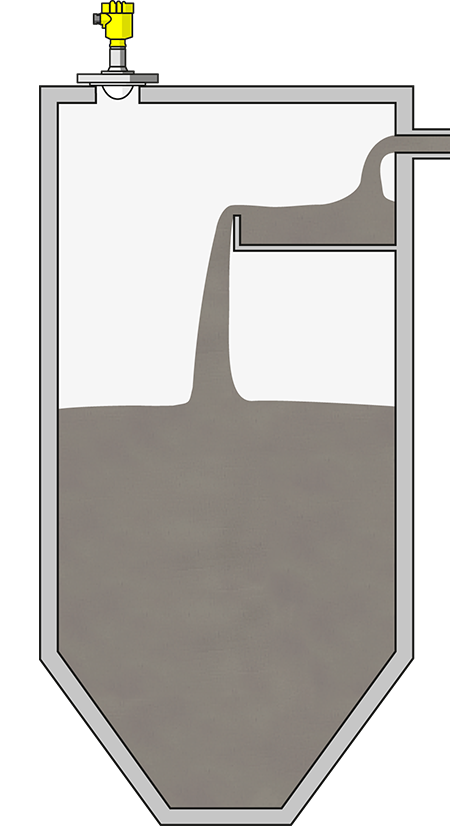

Pump tank

Level measurement in a pump tank

Process data

Measuring task

Level measurement

Measuring point

Tank

Measuring range up to

4 m

Medium

Mixture of bauxite, lime, sodium hydroxide

Process temperature

+30 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Limited space, condensation, buildup, corrosion

Application

Bauxite, lime and sodium hydroxide are ground and mixed in a ball mill – the mixture turns into a red slurry, which is then conveyed into the pumping tank. Some of the balls from the mill can potentially enter the tank along with the slurry. To prevent this from happening, the balls are collected in a weir arrangement, which overflows into the main tank. Level measurement in the tank avoids dry running of the pump and ensures a continuous process.

Your benefit

Reliable

Reliable measurement even during filling

Cost effective

Reliable measurement of the entire container volume

User friendly

Simple mounting and setup

Recommended products

VEGAPULS 64

Radar sensor for continuous level measurement in the pump tank

- Unaffected by condensate and deposits on the antenna

- High corrosion resistance to caustic soda

- Maintenance-free through non-contact measurement

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement in a pump tank

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -