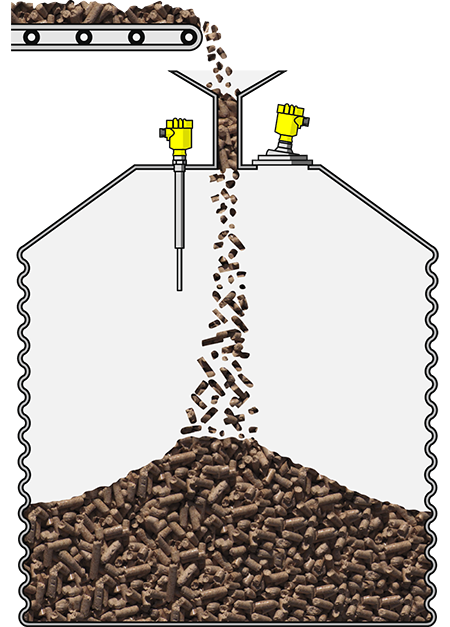

Level measurement and point level detection in a corrugated metal silo

Storage silo for wood pellets

Level measurement and point level detection in a corrugated metal silo

Process data

Measuring task

Level measurement and point level detection

Measuring point

Silo

Measuring range up to

30 m

Medium

Wood pellets

Process temperature

-20 … +40 °C

Process pressure

0 … 0 bar

Features

High dust levels, temperature fluctuations and highly corrugated container walls

Application

The finished pellets are stored ready for delivery in corrugated metal silos up to and over 30 m high. Larger storage volumes allow the supplier to better respond to the increased demand during the heating season and utilize the production equipment continuously throughout the year. For optimal planning of material logistics, a reliable measurement of silo contents is a must.

Your benefit

Reliable

Highly dependable and accurate level measurement, even during filling

Cost effective

By optimising silo volumes, it results in better utilization of production capacity

User friendly

Simple mounting, installation from top

Recommended Products

VEGAPULS 69

Non-contact level measurement with radar in the pellet silo.

- Wear-free thanks to non-contact measurement

- Easy mounting and setup due to top installation

-

Good focusing of the radar beam enables sure measurement even during filling and with corrugated walls

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

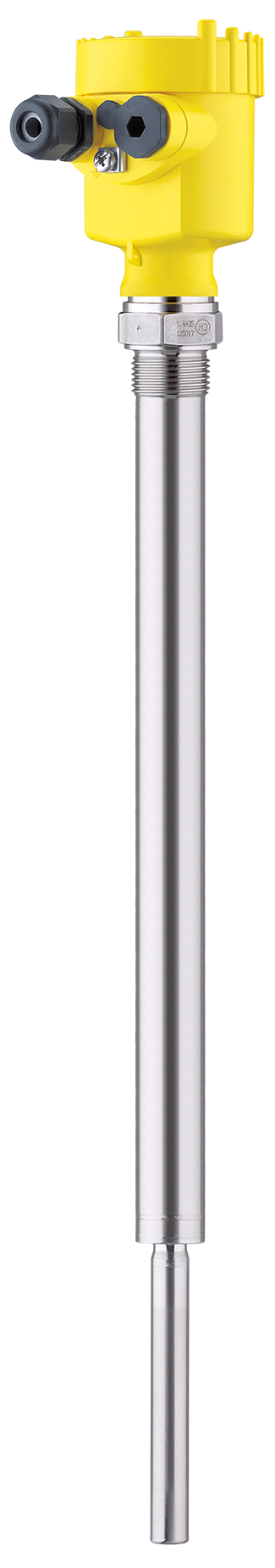

VEGAVIB 63

Point level detection with vibrating level switch in the storage silo

- Reliable level signal under all operating conditions

- Wear and maintenance-free

- Easy to install and adjustment-free

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 16 bar

Version

Detection of solids in water

with tube extension

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement and point level detection in a corrugated metal silo

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -