Quantity measurement on the feed belt to the coal mill

Feed belt to the coal mill

Quantity measurement on the feed belt to the coal mill

|

|

Process data

Measuring task

Level measurement

Measuring point

Feed belt

Measuring range up to

1 m

Medium

Hard coal and brown coal

Process temperature

-40 … +50 °C

Process pressure

0 … 0 bar

Special challenges

Small measuring ranges, dust, belt speed

Application

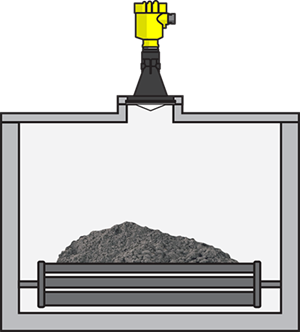

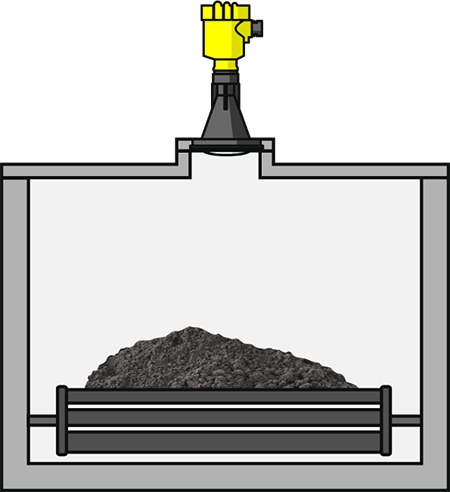

To fuel the power plant boilers, chain conveyors must first bring raw coal from the bunkers. Feed belts (distributors) then transport the coal to the coal mill, where it is ground into dust and blown into the boiler. In order to ensure the fuel supply to the boiler in periods of full load, and especially low load, three redundant measuring systems are employed per feed belt.

Your benefit

Reliable

Reliable monitoring of chain conveyor loading

Cost effective

Optimal plant operation

User friendly

Simple installation without mounting system

Recommended Products

VEGAPULS 67

Non-contact level measurement with radar for monitoring the feed belts to the coal mill

- Non-contact, maintenance-free measurement

- Reliable measurement even with small measuring ranges

- High measurement certainty in spite of intense dust generation

-

High operational reliability even on high belt speeds

Measuring range - Distance

15 m

Process temperature

-40 ... 80 °C

Process pressure

-1 ... 2 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Quantity measurement on the feed belt to the coal mill

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -