Cooling tower basin level measurement

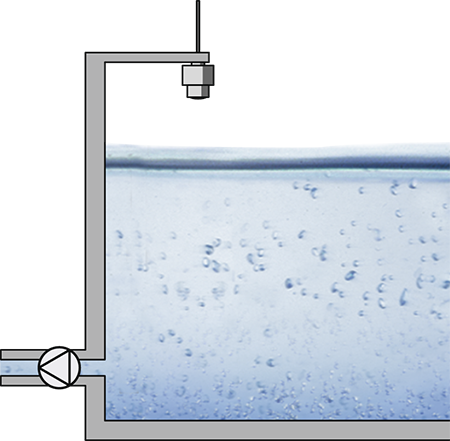

Cooling tower basin

Cooling tower basin level measurement

|

|

Process data

Measuring task

Level measurement

Measuring point

Cooling tower basin

Measuring range up to

5 m

Medium

Water

Process temperature

+20 … +40 °C

Process pressure

0 … 0 bar

Special challenges

High humidity and steam

Application

At the bottom of the cooling tower there are nozzles for atomizing and cooling incoming hot water. As the heated water is sprayed up inside the cooling tower, it warms the air, which expands, flows upward creating updraft which pulls fresh cold air up through the slatted bottom. Draft eliminators inside the cooling tower cause the cooled water to form droplets and rain back down into the cooling tower basin. The water level in the cooling tower basin must be monitored continuously to optimise use of the circulation pumps and the cooling process.

Your benefit

Reliable

Reliable operation under all operating conditions

Cost effective

Maintenance-free operation of the plant

User friendly

Simple mounting and setup

Recommended Products

VEGAFLEX 81

Level measurement with guided radar in the cooling tower basin

- Simple, maintenance-free measurement

- High measurement certainty, even in extremely wet conditions, independent of pressure fluctuations

- Proven measuring principle ensures high operational reliability

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Cooling tower basin level measurement

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -