Level measurement in the diazotization vessel

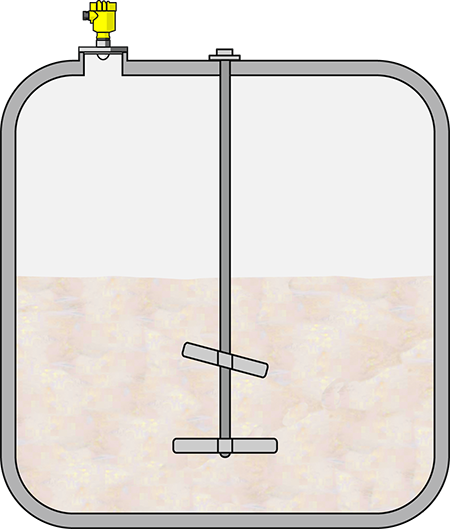

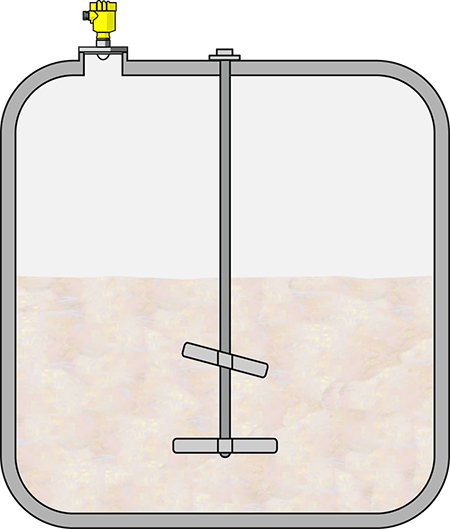

Diazotization vessel

Level measurement in the diazotization vessel

|

|

Process data

Measuring task

Level measurement

Measuring point

Tank

Measuring range up to

4 m

Medium

Sodium nitrite, aniline, acid

Process temperature

+20 ... +24 °C

Process pressure

0 … 0 bar

Special challenges

Aggressive media

Application

In the diazotization process, the individual raw materials for colour pigment production are prepared so that they will react to become diazonium compounds ready for the subsequent ‘coupling’ vessel where they form the final crude pigment or ‘azo dye’. The basic starting materials for these compounds are hydrochloric acid, water, sodium nitrite and the diazo component (usually aniline). To preserve the material quality during formulation, the mixture is kept cool by adding ice or via a cooling jacket. During this process, the level must be carefully monitored and kept constant.

Your benefit

Reliable

Accurate measurement unaffected by changing product properties

Cost effective

Maintenance-free operation thanks to non-contact measurement technology

User friendly

Simple installation from above

Recommended products

VEGAPULS 64

Non-contact level measurement with radar in the diazotization vessel

- Encapsulated antenna system prevents buildup

- PTFE antenna resistant to chemically aggressive media

- Maintenance-free operation thanks to non-contact measuring method

Measuring range - Distance

30 m

Process temperature

-196 ... 200 °C

Process pressure

-1 ... 25 bar

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement in the diazotization vessel

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -