Level measurement and point level detection in silos

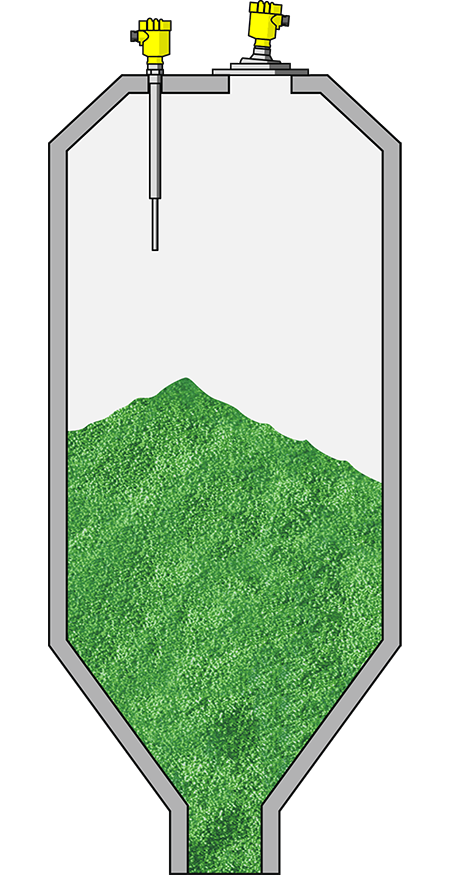

Silos for bulk solids

Level measurement and point level detection in silos

|

|

Process data

Measuring task

Level measurement and point level detection

Measuring point

Silo, stockpile, bunker

Measuring range up to

80 m

Medium

Granulated bulk solids

Process temperature

-40 … +200 °C

Process pressure

-1 … +3 bar

Special challenges

Dust, filling noise, changes in media properties, abrasive media

Application

In the chemical industry, many different kinds of bulk solids are produced or used as raw materials. To ensure reliable measurement of silo contents, many factors must be considered: different bulk densities, abrasive properties, dust generation and the requirements of explosion protection. Implementation of the most suitable level sensors ensures optimal production planning and reliable logistics for the finished products.

Your benefit

Reliable

Reliable measurement, independent of media properties and container geometry

Cost effective

Maintenance-free operation

User friendly

Universally applicable for almost all bulk solids

Recommended products

VEGAPULS 69

Non-contact radar level measurement in bulk solids silos

- Reliable measurement even with large amounts of dust and filling noise

- Suitable even for high, narrow silos or segmented containers, thanks to good signal focusing

- Can be used in media of differing consistency and in different measuring ranges

- Simple installation and calibration, even on filled silos

Measuring range - Distance

120 m

Process temperature

-40 ... 200 °C

Process pressure

-1 ... 20 bar

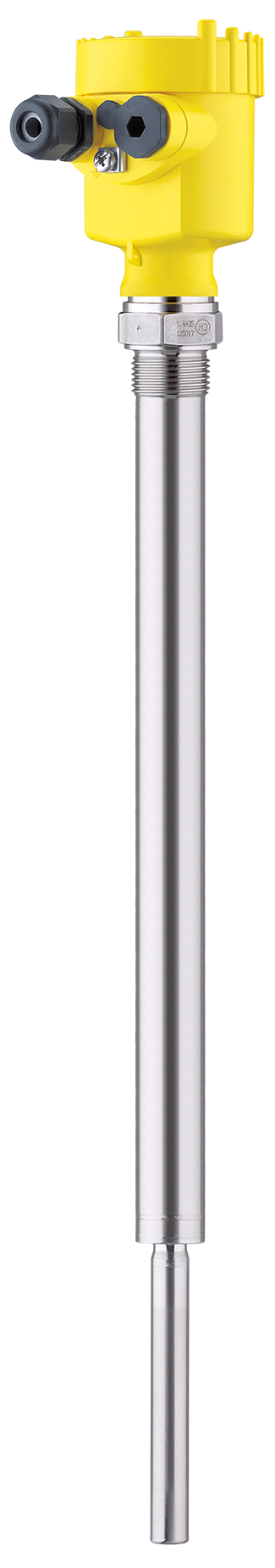

VEGAVIB 63

Point level detection with vibrating level switches in bulk solids silos

- Universally applicable for all granulated bulk solids

- Wear and maintenance-free measurement

- Simple, adjustment-free setup and commissioning

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 16 bar

Version

Detection of solids in water

with tube extension

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Level measurement and point level detection in silos

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -