Monitoring of filters in drinking water supplies

Filter monitoring

Monitoring of filters in drinking water supplies

Process data

Measuring task

Differential pressure measurement

Measuring point

Filter

Measuring range up to

0.8 m

Medium

Fresh water

Process temperature

+3 … +10 °C

Process pressure

-0.5 … +2 bar

Special challenges

Abrasion

Application

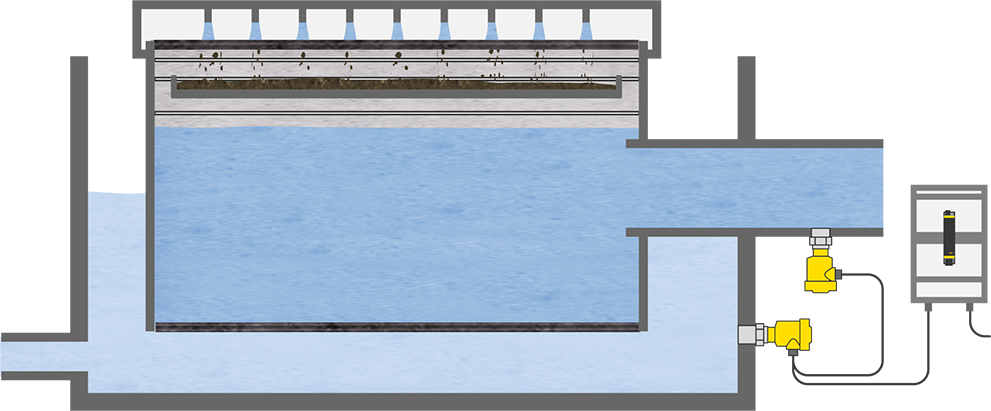

The raw water is pumped from the lake into a tank. It is then filtered via a drum filter. In this process the water is separated and purified from any suspended matter and coarse impurities. An electronic differential pressure measuring instrument monitors the level of contamination of the filter. Cleaning of the filter is automatically triggered as soon as the threshold contamination is exceeded.

Your benefit

Reliable

Approved materials according to FDA and EC 1935/2004, as well as local certification

Cost effective

Simple installation, with two sensors interconnected via a single cable

User friendly

Multivariable sensor: differential pressure, static pressure and temperature

Recommended products

VEGABAR 82

Filter monitoring via electronic differential pressure measurement

- Long-term stability and reliability thanks to the use of moisture-proof measuring cell

- Integrated temperature sensor saves purchase of additional temperature measuring instruments

- Highly resistant to abrasive particles thanks to the ceramic CERTEC® measuring cell

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 100 bar

Process temperature

-40 ... 150 °C

VEGATRENN 141

Separator for the optimum supply of power to the connected sensors

- On-site diagnostics for direct display of status via LEDs

- Simple parametrization interface using the HART sockets for user-friendly operation

- Galvanic separation of sensors and PLC is secured

Protection rating

IP 20

Input

1 x 4 … 20 mA/HART sensor input

Output

1 x 4 … 20 mA

Sorry, Currently No Video Uploaded.

Sorry, Currently No File Uploaded.

Monitoring of filters in drinking water supplies

Please Leave Your Product Enquiry Here. We will Get Back To You Soon.

Product Specifications

- Product SKU : -

- Weight (GRAM) : -

- Dimension : -